Beijing’s Design Standard for Energy Efficiency of Residential Buildings coming into effect on January 1, 2021 includes two major upgrades: to boost the building energy efficiency rate from 75% to more than 80% by increasing the thickness of exterior wall insulation and lowering the Thermal transmittance (K-value) to less than 1.1 W/(㎡·K). In the light of the new building energy-saving design regulations, provinces and cities are expected to roll out the corresponding building energy-saving standards soon. Enterprises in construction and building materials related business will also face the opportunity to take off or the life-or-death challenges.

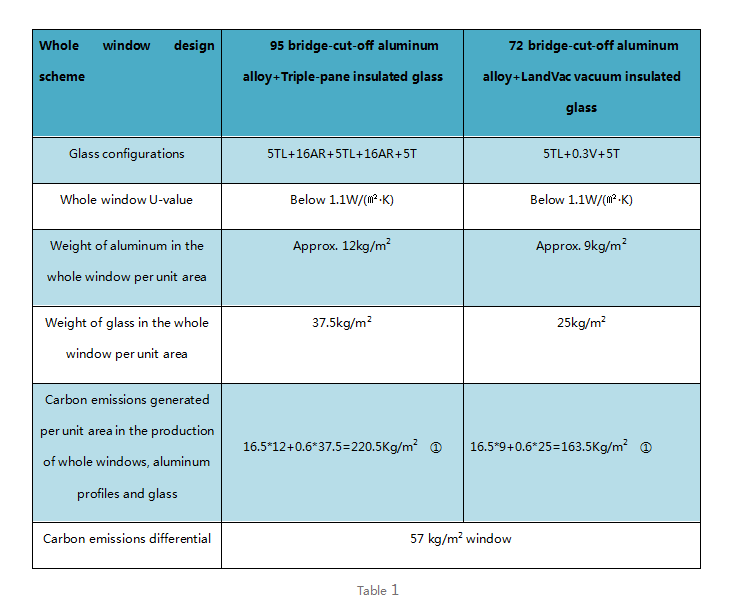

While windows and doors only account for 10% of a building envelope, the energy loss caused by them is often responsible for 40% of the total building energy consumption. As the sizes of today’s doors and windows are getting larger and the curtain walls become increasingly popular, the opportunities for more than 5,000 fenestration manufacturers nationwide cannot be ignored. At present, the mainstream whole window scheme on the market with a K-value below 1.1 is the 95 bridge-cut-off aluminum alloy frame with triple-pane insulated glass configuration. Compared with the LandVac 72 bridge-cut-off aluminum alloy frame solution, the carbon emissions generated in manufacturing its additional aluminum profiles and glass amount to 57Kg/m2. See Table 1.

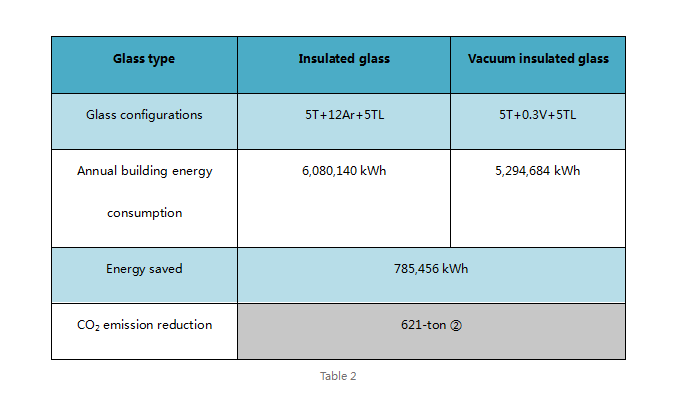

Compared with insulated glass, when a commercial building with a floor space of 40,000 square meters adopts LandVac in its entire fenestration system, it can save approximately 580,000 yuan a year in electricity bills and reduce carbon emissions by approximately 600 tons. See Table 2.

Thus, the wide application of and replacement with vacuum insulated glass will significantly reduce the use of glass and aluminum materials, resulting in continuous energy-saving and emission reduction effects. It will be conducive to the reduction of total carbon emissions in the construction sector, which will contribute to the realization of a peak in CO2 emissions before 2030 and carbon neutrality before 2060 for China’s right to develop toward the great goal of national rejuvenation!

Note:

①According to 2020 data released by International Aluminum Institute (IAI): 16.8-ton of CO2 emission for each ton of aluminum produced; according to data of Networked Carbon Markets: For each ton of glass produced, approximately 600Kg of CO2 is emitted;

② The data are derived from a commercial building in Luoyang (a cold region) with a floor space of approximately 40,000 square meters and fenestration area of approximately 10,000 square meters. Due to space limitations, other conditions and data are deemed negligible.