How to achieve automation management throughout the entire process?

How to reduce human errors and labor cost?

How to minimize the cost for supply and storage?

How to achieve standardized production for products with multi-specifications?

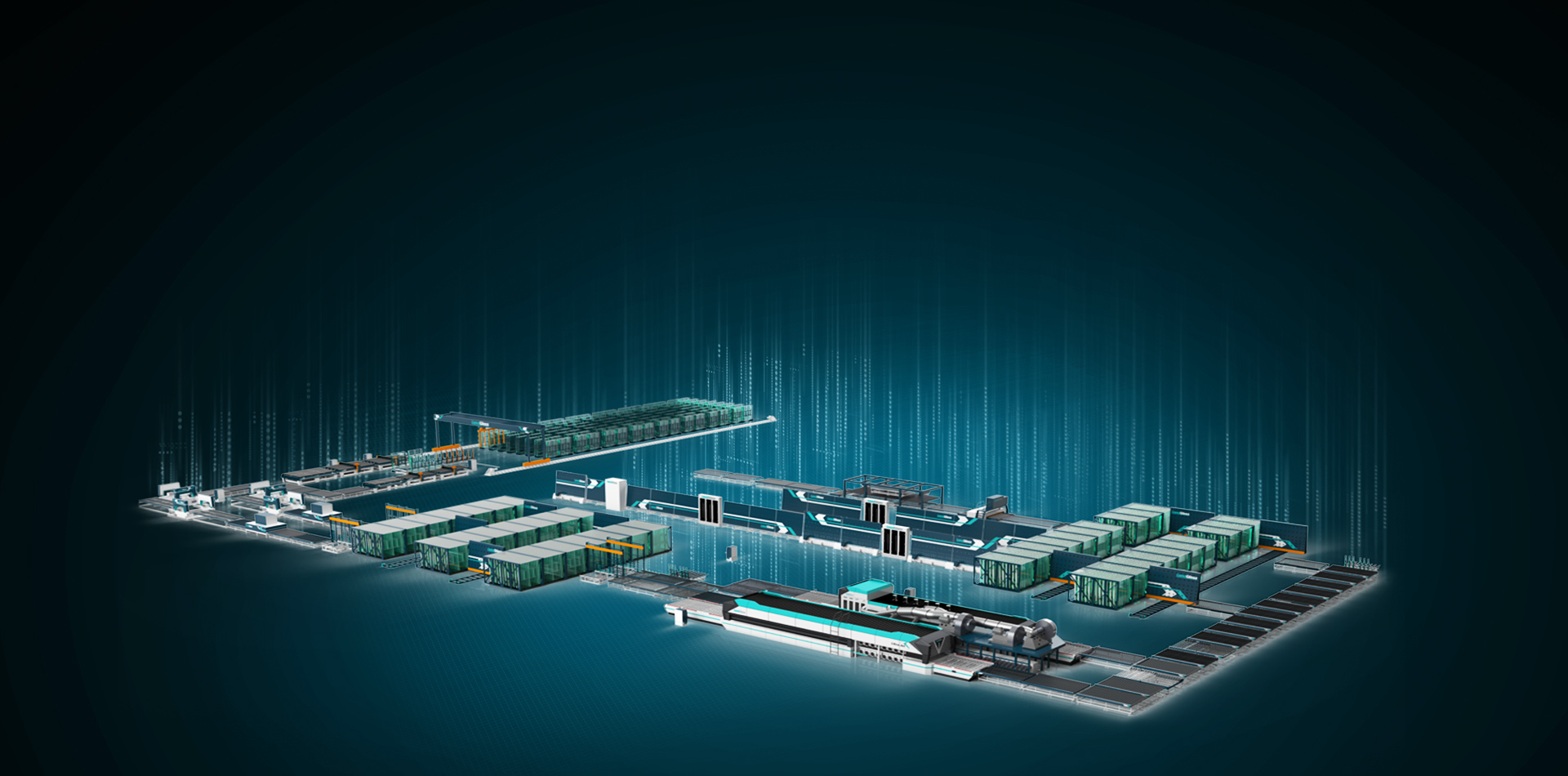

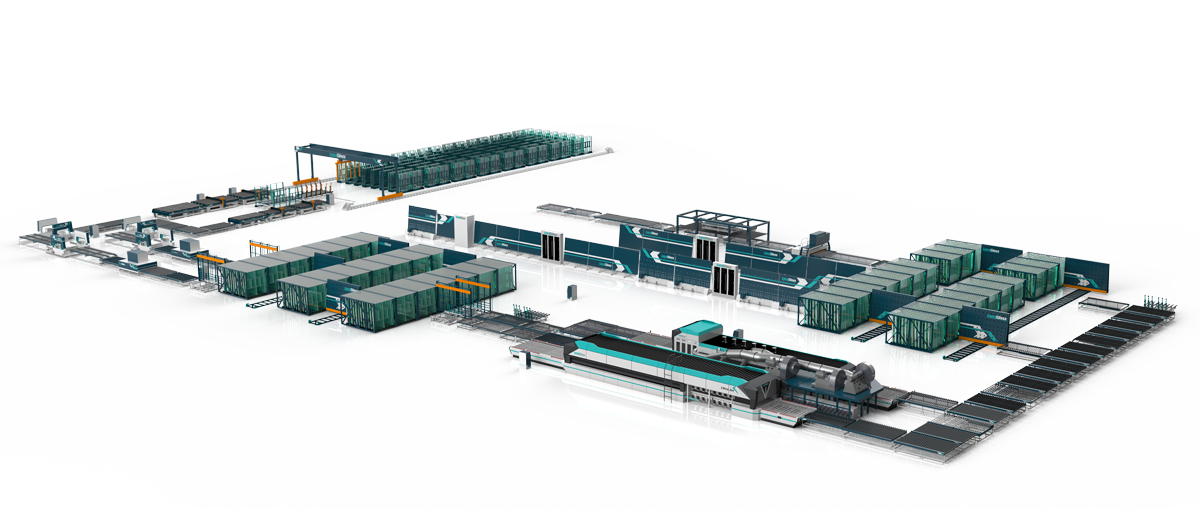

LandGlass LandTiger Series smart factory brings you to the future of glass processing!

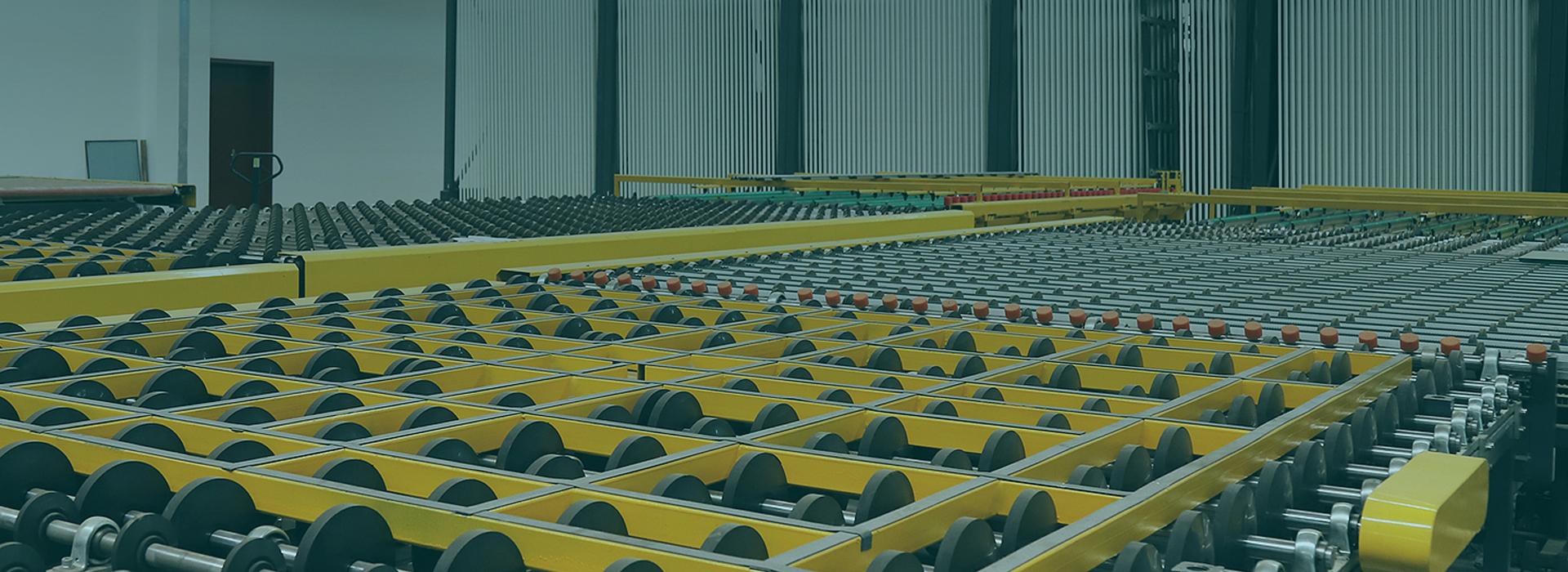

LandGlass LandTiger Series Smart Factory employs the new generation enterprise resource planning system, intelligent manufacturing technology and identification technology to interconnect all machinery throughout the entire process from float glass to finished products. It has realized digital and intelligent processing of supply, manufacturing, and sales information during production, achieving lean and efficient manufacturing and management.

The smart factory of LandGlass has achieved intuitive management of the manufacturing process through comprehensive aggregation and real-time analysis of labor and equipment data collected and integrated from all manufacturing processes. The intelligent software and services maximized productivity for the benefit of our customers. The major advantages of LandGlass smart factory include: efficient production process, excellent quality assurance, comprehensive equipment management, streamlined staffing, etc. The details are as follows: